Specification

- मार्किंग एरिया

- 110 mm x 110 mm (Standard)

- मार्किंग स्पीड

- 7000 mm/s

- शर्त

- लेजर का प्रकार

- सीएनसी

- Yes

- कूलिंग मोड

- कंट्रोल सॉफ्टवेयर

- EZCAD

- सटीकता

- ±0.01 mm

- पावर

- 20W / 30W / 50W

- आयाम

- 800 mm x 650 mm x 1450 mm

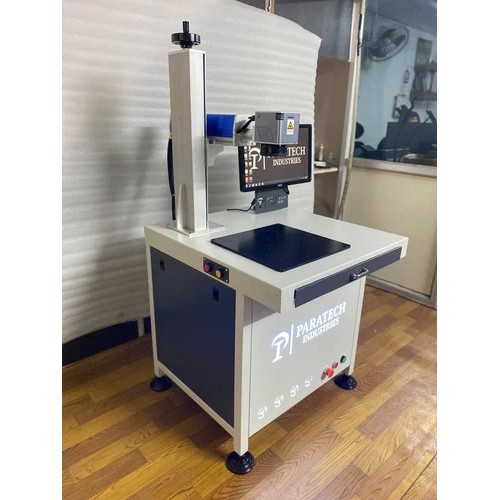

About

Laser Marking Machines employ laser technology to etch orengrave accurate lines that are permanent onto a range of materials. Due totheir adaptability, accuracy, and efficiency, these machines have been widelyused in a variety of sectors. High-powered lasers are used by laser markingmachines to imprint markings, patterns, or codes on materials. Due to itsadaptability to different applications, these machines may be used in a varietyof sectors, including automotive, aerospace, electronics, medical, jewelry, andmore. High-speed operation of these machines ensures effective output andlittle downtime.

| Marking Speed Capacity | 8000 mm/s |

| Usage/Application | MARKING ON VARIOUS MATERIAL |

| Laser Type | Fiber Laser |

| Marking Depth | AS PER CUSTOMER REQUIREMRNTS |

| Model Name/Number | PI-20 |

| One pass (depends on material) | DEPEND ON MATERIALS |

| Min Line Width | 0.01 MM |

| Minimum Line Width | 0.1 MM |

| Whole Machine Power | 1 KW |

| Maximum working Area | 300X300 MM AREA |

| Power | 20/30/50 |

Unmatched Precision and Speed

Achieve ultra-fine markings with a minimum character size of just 0.2 mm and line widths down to 0.015 mm. With a focused spot diameter under 0.01 mm and marking speeds reaching up to 7000 mm/s, this fiber laser ensures clean, sharp, and repeatable results even on intricate designs, making it ideal for detailed industrial applications.

Versatile Material Compatibility

Engineered to work seamlessly with metals, plastics, ceramics, rubber, leather, and more, this machine adapts to a broad range of industrial marking requirements. Whether you're engraving serial numbers or branding components, it delivers consistent results across various substrates.

Ease of Use and Integration

The laser marking machine features user-friendly EZCAD control software, supporting file formats like AI, DXF, PLT, BMP, and JPG. Its CNC compatibility and simple air cooling system facilitate effortless integration into existing production lines, while robust build quality ensures durability in environments with 5%-85% non-condensing humidity.

FAQ's of industrial Laser Marking Machines:

Q: How does the laser marking machine ensure high marking accuracy?

A: The machine operates with a focused spot diameter of less than 0.01 mm, achieving an accuracy of 0.01 mm. This enables precise marking of fine lines and small characters, making it suitable for demanding industrial tasks that require high definition.Q: What materials can be marked with this fiber laser machine?

A: This model efficiently marks metals, plastics, ceramics, rubber, leather, and more, making it versatile for a wide range of manufacturing and branding requirements.Q: When is air cooling beneficial for this machine?

A: Air cooling is highly effective for maintaining the optimal operating temperature (0C~40C) of the fiber laser. It ensures consistent performance, minimizes maintenance needs, and makes the system suitable for continuous heavy-duty operation.Q: Where can this laser marking machine be installed?

A: With standard dimensions of 800 mm x 650 mm x 1450 mm and an approximate weight of 80 kg, the machine fits well in industrial environments such as workshops, manufacturing plants, and exporting facilities. It operates efficiently in conditions with 5%-85% environmental humidity, non-condensing.Q: What is the process for marking using this machine?

A: Users import designs or codes in formats like AI, DXF, PLT, BMP, or JPG into the EZCAD control software. The integrated CNC system manages positioning, and marking is completed at speeds up to 7000 mm/s, suitable for both batch and individual production workflows.Q: How does using this laser machine benefit industrial production?

A: It provides permanent, non-contact, high-speed markings with minimal maintenance. The precise and customizable output boosts efficiency, enhances product traceability, and minimizes downtime, improving overall production quality and reliability.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in फाइबर लेजर मार्किंग मशीन Category

थाली सेट लेज़र मार्किंग मशीन

शर्त : नया

न्यूनतम आदेश मात्रा : 1

माप की इकाई : यूनिट/यूनिट

मूल्य की इकाई : यूनिट/यूनिट

लेजर का प्रकार : फाइबर लेजर

वारंटी : उपलब्ध

डोर हार्डवेयर लेजर मार्किंग मशीन

शर्त : नया

न्यूनतम आदेश मात्रा : 1

माप की इकाई : यूनिट/यूनिट

मूल्य की इकाई : यूनिट/यूनिट

लेजर का प्रकार : फाइबर लेजर

वारंटी : उपलब्ध

मेटल मार्किंग लेजर मशीन

शर्त : नया

न्यूनतम आदेश मात्रा : 1

माप की इकाई : यूनिट/यूनिट

मूल्य की इकाई : यूनिट/यूनिट

लेजर का प्रकार : फाइबर लेजर

वारंटी : उपलब्ध

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese