Price 140000.00 आईएनआर/ Set

Specification

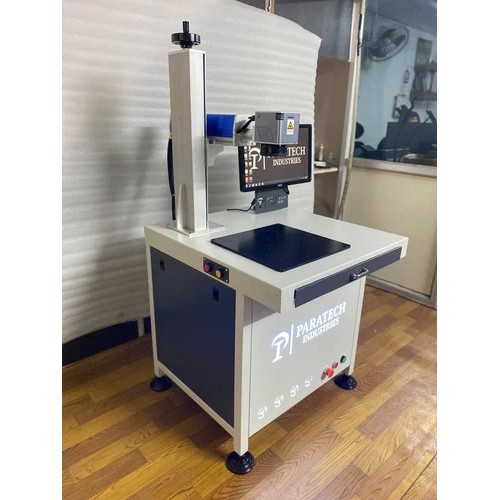

- मार्किंग एरिया

- 110mm x 110mm / 200mm x 200mm (optional)

- मार्किंग स्पीड

- 7000mm/s

- शर्त

- लेजर का प्रकार

- सीएनसी

- Yes

- कूलिंग मोड

- कंट्रोल सॉफ्टवेयर

- EZCAD

- सटीकता

- ±0.01 mm

- पावर

- 20W / 30W / 50W (optional)

- आयाम

- 800mm x 650mm x 1450mm

About

Laser Marking Machines employ laser technology to etch orengrave accurate lines that are permanent onto a range of materials. Due totheir adaptability, accuracy, and efficiency, these machines have been widelyused in a variety of sectors. High-powered lasers are used by laser markingmachines to imprint markings, patterns, or codes on materials. Due to itsadaptability to different applications, these machines may be used in a varietyof sectors, including automotive, aerospace, electronics, medical, jewelry, andmore. High-speed operation of these machines ensures effective output andlittle downtime.

Advanced Precision for Industrial Marking

Achieve unmatched detail and accuracy with this technologically advanced fiber laser marking machine. It is purpose-built for black plate marking and offers precise control with a 0.01mm minimum line width. Leveraging a potent wavelength and high pulse frequency, it ensures clean and crisp marks on a wide range of materials, making it an excellent choice for industries that demand top-notch quality in product labeling and traceability.

Flexible Power and Versatile Applications

Choose from 20W, 30W, or 50W power options to tailor the machine to your specific operational requirements. The device is compatible with multiple materials such as metal, black plate, stainless steel, and plastics, enabling broad industrial usage. With supported graphic formats like DXF, PLT, and JPEG, design flexibility is maximized for various marking applications.

User-Friendly Operation and Reliable Construction

Designed with industrial usability in mind, the marking machine features intuitive EZCAD software, a red light pointer for ideal focus, and convenient USB/RS232 connectivity. Its air cooling system and robust build ensure consistent performance within a broad temperature range. The new CNC-enabled system is suitable for high-speed usage and covers marking areas of 110mm x 110mm or 200mm x 200mm.

FAQ's of The Best Marking Machine For Black Plate Marking:

Q: How does the marking process work on black plates using this machine?

A: This fiber laser marking machine utilizes a focused 1064nm wavelength beam that interacts with the black plate material to create highly visible, permanent marks. The red light pointer assists with precise focus, and the system is controlled using EZCAD software. Users can input designs in various formats (like DXF or JPEG), and the laser accurately engraves the specified area, achieving detailed lines down to 0.01mm in width.Q: What types of materials can this machine mark besides black plates?

A: In addition to black plates, the machine is compatible with metals, stainless steel, plastics, and other industrial materials. Its powerful laser and flexible focus make it suitable for marking a variety of substrates used commonly in manufacturing and export industries.Q: When is this machine most suitable for use?

A: This marking machine is ideal for deployment in environments that require high-accuracy, high-speed, and permanent marking solutions, such as manufacturing plants, industrial workshops, and production lines. It is designed for continuous operation within 0C to 45C, making it dependable throughout a wide range of industrial settings.Q: Where can this marking machine be integrated?

A: The machine is suitable for installation in industrial environments across India and can be set up in manufacturing facilities, export units, or workshops. Its standard dimensions and air cooling system allow it to fit conveniently into existing production spaces without specialized infrastructure.Q: What are the main benefits of using this marking machine for black plate applications?

A: Benefits include exceptional marking accuracy of 0.01 mm, high marking speed up to 7000mm/s, and flexibility with supported file formats and marking areas. Its robust engineering ensures reliable operation with low maintenance, and the fiber laser is energy-efficient and durable, ensuring long-term cost savings.Q: How is the machine controlled and operated?

A: Operation is streamlined with EZCAD control software, allowing users to import graphics and designs easily. The machine connects via USB or RS232, and the CNC-driven system ensures automated, precise movements for repeatable marking quality. The red light pointer aids in efficient setup and alignment.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in फाइबर लेजर मार्किंग मशीन Category

थाली सेट लेज़र मार्किंग मशीन

माप की इकाई : यूनिट/यूनिट

शर्त : नया

मूल्य की इकाई : यूनिट/यूनिट

न्यूनतम आदेश मात्रा : 1

लेजर का प्रकार : फाइबर लेजर

वारंटी : उपलब्ध

परम लेजर मार्किंग मशीन

माप की इकाई : यूनिट/यूनिट

शर्त : नया

मूल्य की इकाई : यूनिट/यूनिट

न्यूनतम आदेश मात्रा : 1

लेजर का प्रकार : फाइबर लेजर

वारंटी : उपलब्ध

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese